About Hooks

All hooks are not the same. They are made very similarly though. Metal wire of different diameter is heated and bent into a prescribed shape which is a specific "hook pattern" (shape and style, not to be confused with a fly pattern) which determines the type of eye, length, bend and point of that hook type. The shaped hook is heated again (tempered) which determines the hardness of the metal hook and keeps it from bending. You may find some hooks breaking easily on you. This usually means it has gotten too hot in the temper process and is brittle. Hooks that bend easily have not gotten hot enough. Hooks can be sharpened chemically or physically. A chemically sharpened hook is "filed" with a solvent and can produce a very precise point. The hooks are then usually covered with a coating to resist rusting.

Hooks come in a variety of styles and sizes. Generally speaking, the hook size refers to the hook gape(see below). One hook "pattern" will likely be available in many sizes. Common sizes range from 0 into the 20's with 0 being the larger and 20 being the smaller hook. The size is denoted by (#). The larger the number the smaller the hook. Any hook larger than a #0 becomes an "aught" system (#1/0, #2/0, #3/0....) where the larger the number the larger the hook. Are you confused yet? Most sizes we work with on this site will be in the #6-#18 size range. Most hooks will be available in even size increments only (#2,#4, #6, #8,#10...etc). There are some exceptions though. It is also important to note that sizing is only a general indicator. A #14 from one manufacturer may be slightly different than a #14 from another manufacturer. Close but not the same.

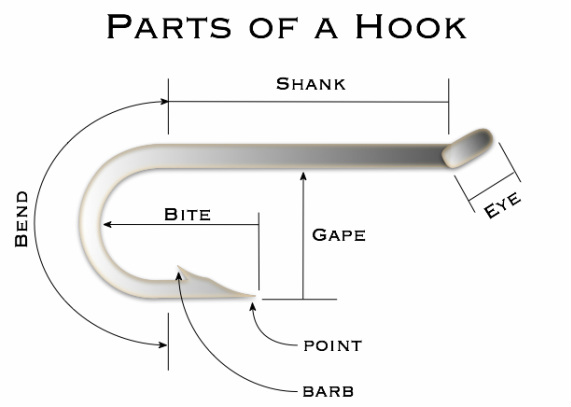

As experience in tying grows, the tier will naturally gravitate toward certain styles or manufacturers which they prefer. This is usually a personal preference based on a balance between the hook pattern a manufacturer offers, the type of flies the tier most often ties, functionality of hook design and value. The vast majority of manufacturers today make strong, sharp, good quality hooks. The functional tier should concern themselves more with the properties of hook shape and weight when choosing a hook for a particular pattern. It is import to learn the basic parts of a hook. Through out the lessons on this site I will use certain parts of the hook as guidelines in the placement techniques. Below is a diagram of the parts of a hook and then some discussion of the properties of a hook that are most concerning to the tier.

Wire diameter

A vast majority of hooks made for freshwater fly fishing are crafted from a high carbon content steel wire. The wire is available in multiple diameters so the manufacturer can make hooks of all the various sizes while still retaining a comparable strength relationship throughout. Another feature is the tier is often given a choice of hook diameter. A specific #12 hook pattern may be available in different diameter wire. This is very convenient to the tier and especially to the wet fly tier. With a combination of thoughtful selection of materials, fly profile, presentation and hook diameter there is a quite a range of fishing depth that can be achieved. Each manufacturer will have a set "standard" hook diameter for specific sizes and styles. Any deviation from the standard will be noted in the hook description. Often you will see, "heavy wire hook" or "fine wire hook" denoting a thicker or thinner diameter wire from the standard was used. Some manufacturers will use an "X" system along with a number denoting the deviation from the standard. A 2x heavy hook would be 2 times thicker than the standard. Not necessarily double the diameter but two increases in diameter. The same would be for 1x fine hook but with a single decrease in diameter. This is a very important feature of hook choice when a tier is purposefully tying a pattern to for a specific scenario.

The eye of the hook

Most hooks today have a formed circular eye at the most forward position of the hook. There are many shapes used in the hook industry to form the eye. The three most common are the ball, the tapered and the looped eye. The ball eye is probably the most common one you will find. This will be tapered or un-tapered. The ball eye can be found "open" or "closed" with closed being considerably stronger. The tapered eye is used mostly on dry fly hooks to reduce the overall weight of the hook. The looped eye is predominantly found on salmon hooks and some streamers. The loop can be found tapered or un-tapered as well.

Besides having different shaped loops, the eye of the hook can be found bent down, bent up, or ringed(straight). This will often be abbreviated TDE (down eye), TUE (up eye) or RE (ring eye or straight). The difference between the three is arguably more cosmetic than functional. However, there are many fly fishers in the theory of a slight functional difference. The difference may be more about a relationship with the shape of the hook bend and the type of knot used to attach the fly to the tippet. I may add more about this later, but for now we can consider the difference mostly cosmetic.

Most hooks today have a formed circular eye at the most forward position of the hook. There are many shapes used in the hook industry to form the eye. The three most common are the ball, the tapered and the looped eye. The ball eye is probably the most common one you will find. This will be tapered or un-tapered. The ball eye can be found "open" or "closed" with closed being considerably stronger. The tapered eye is used mostly on dry fly hooks to reduce the overall weight of the hook. The looped eye is predominantly found on salmon hooks and some streamers. The loop can be found tapered or un-tapered as well.

Besides having different shaped loops, the eye of the hook can be found bent down, bent up, or ringed(straight). This will often be abbreviated TDE (down eye), TUE (up eye) or RE (ring eye or straight). The difference between the three is arguably more cosmetic than functional. However, there are many fly fishers in the theory of a slight functional difference. The difference may be more about a relationship with the shape of the hook bend and the type of knot used to attach the fly to the tippet. I may add more about this later, but for now we can consider the difference mostly cosmetic.

The hook shank

The shank of the hook is the straight section along the top of the hook that extends from the back of the eye to the beginning of the hook bend. This section has a direct relationship with the length of the hook. Curved shank hooks are very popular today. The shank of a curved hook is somewhat left to the discrepancy of the tier. The properties of the shank that most concern the tier are the length of the shank section and whether or not you want to use a curved or straight profile. On a straight shank hook, the length will be a part of the the hook's official description. "Standard" length is determined by each manufacturer for various styles. From there, the length of the hook will be noted by a number and an "x" (1x, 2x, 3x) . For example, "2x" would be two times removed from the standard. To complicate things a bit more, this can go either direction. A hook can be 3x longer or 2x shorter than a set standard length. Most hook descriptions will list something like... "3x long" or "2x short" or "standard length".

What does this mean to the purposeful tier? The shank is the foundation you build your pattern upon. The bulk of tying will take place on the shank. It will determine the general length and shape of your imitation. If the natural insect is a stonefly with a long body choose a longer shanked hook. If it is a short fat clinging mayfly then a shorter shanked hook will be more desired. If the imitation is intended to drift along with the current, a curved shank hook to imitated the profile many insects take as they drift downstream might be considered. Selection of these attributes of the hook shank should be determined by what is being imitated and how the pattern is going to be presented.

The shank of the hook is the straight section along the top of the hook that extends from the back of the eye to the beginning of the hook bend. This section has a direct relationship with the length of the hook. Curved shank hooks are very popular today. The shank of a curved hook is somewhat left to the discrepancy of the tier. The properties of the shank that most concern the tier are the length of the shank section and whether or not you want to use a curved or straight profile. On a straight shank hook, the length will be a part of the the hook's official description. "Standard" length is determined by each manufacturer for various styles. From there, the length of the hook will be noted by a number and an "x" (1x, 2x, 3x) . For example, "2x" would be two times removed from the standard. To complicate things a bit more, this can go either direction. A hook can be 3x longer or 2x shorter than a set standard length. Most hook descriptions will list something like... "3x long" or "2x short" or "standard length".

What does this mean to the purposeful tier? The shank is the foundation you build your pattern upon. The bulk of tying will take place on the shank. It will determine the general length and shape of your imitation. If the natural insect is a stonefly with a long body choose a longer shanked hook. If it is a short fat clinging mayfly then a shorter shanked hook will be more desired. If the imitation is intended to drift along with the current, a curved shank hook to imitated the profile many insects take as they drift downstream might be considered. Selection of these attributes of the hook shank should be determined by what is being imitated and how the pattern is going to be presented.

The bend of the hook

The bend of the hook begins at the rear of the shank and continues around to a point on the bottom of the hook. Where the bend begins and ends can be subjective based on the over all hook design. The bend is available in a variety of shapes. Each shape will provide a different effect on the hooking and holding abilities of the hook and also the overall shape of the final fly pattern. The most common shapes for fly fishing today include: round or perfect, sproat and limerick, however quite a few others can be found. The shapes available are all adequate for hooking fish and there isn't any one better than another on it's own. The type of bend in conjunction with all the other features of the hook will determine how well it functions under different circumstances.

The bend of the hook begins at the rear of the shank and continues around to a point on the bottom of the hook. Where the bend begins and ends can be subjective based on the over all hook design. The bend is available in a variety of shapes. Each shape will provide a different effect on the hooking and holding abilities of the hook and also the overall shape of the final fly pattern. The most common shapes for fly fishing today include: round or perfect, sproat and limerick, however quite a few others can be found. The shapes available are all adequate for hooking fish and there isn't any one better than another on it's own. The type of bend in conjunction with all the other features of the hook will determine how well it functions under different circumstances.

The point and barb of the hook

The point is the sharp end at the base of the hook and is often complimented by the barb. The point allows the hook to penetrate, the barb makes it difficult for the hook to dislodge. Some hooks are available without the barb (barbless). This attribute is an option for those that like to practice catch-and-release fishing. It is also quite easy to bend the barb flat with a pair of needle-nose pliers or to file it down. Yes, believe it, there is more than one type of hook point. Like the eye and bend of the hook, the point will be less determined by the pattern of fly and more so by personal preference. All the point types will penetrate the fish's mouth very well, as well as the tip of your finger, the bat flying about in early evening, the rattlesnake swimming midstream or your dog on the backcast (don't ask).

The point is the sharp end at the base of the hook and is often complimented by the barb. The point allows the hook to penetrate, the barb makes it difficult for the hook to dislodge. Some hooks are available without the barb (barbless). This attribute is an option for those that like to practice catch-and-release fishing. It is also quite easy to bend the barb flat with a pair of needle-nose pliers or to file it down. Yes, believe it, there is more than one type of hook point. Like the eye and bend of the hook, the point will be less determined by the pattern of fly and more so by personal preference. All the point types will penetrate the fish's mouth very well, as well as the tip of your finger, the bat flying about in early evening, the rattlesnake swimming midstream or your dog on the backcast (don't ask).

The gape and bite of the hook

The gape and bite of the hook, also known as the gap and throat of the hook are more a measurement of space than an actual part of the hook. The gape is the distance from the hook point to the bottom of the shank directly above the point. As mentioned above this is used to determined the size of the hook. However, wide gape hooks are becoming increasingly popular. A wide gape hook keeps all the proportions of a standard hook but increases the gape measurement from standard for a particular size. This is where the hook size would not correlate to the gape dimension and descriptions get blurred a bit. For example, using a #14 wide gape hook, you may find a very similar hook in the same style if you went with a #12 1x short shanked hook. The wide gape hook is convenient for tying a very small pattern on a very small hook while retaining the hooking properties of a larger hook size. It also is good for tying flies with proportional balance.

The bite is another measurement from the point of the hook. The bite describes the distance from the point back to the furthest inside edge of the bend. In other words the distance the hook can penetrate. For tying purposes, the biggest factor here is nicking your thread on the point of the hook. Hooks with a deep bite can be difficult to tie on as the tier must be constantly aware of the hook point and maneuver gracefully around it with each wrap. Hooks with a curved shank often have deep bites.

The gape and bite of the hook, also known as the gap and throat of the hook are more a measurement of space than an actual part of the hook. The gape is the distance from the hook point to the bottom of the shank directly above the point. As mentioned above this is used to determined the size of the hook. However, wide gape hooks are becoming increasingly popular. A wide gape hook keeps all the proportions of a standard hook but increases the gape measurement from standard for a particular size. This is where the hook size would not correlate to the gape dimension and descriptions get blurred a bit. For example, using a #14 wide gape hook, you may find a very similar hook in the same style if you went with a #12 1x short shanked hook. The wide gape hook is convenient for tying a very small pattern on a very small hook while retaining the hooking properties of a larger hook size. It also is good for tying flies with proportional balance.

The bite is another measurement from the point of the hook. The bite describes the distance from the point back to the furthest inside edge of the bend. In other words the distance the hook can penetrate. For tying purposes, the biggest factor here is nicking your thread on the point of the hook. Hooks with a deep bite can be difficult to tie on as the tier must be constantly aware of the hook point and maneuver gracefully around it with each wrap. Hooks with a curved shank often have deep bites.

For some great information on hooks you can visit the O' Mustad & Son A.S. website below

http://www.mustad.no/230912www/products/abouthooks.html

http://www.mustad.no/230912www/products/abouthooks.html